Six Sigma is a quality-control methodology developed in 1986 by Motorola Inc. A process map is a representation of this precise process definition and the practice of process modeling is therefore fundamental to Six Sigma.

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

Lean Six Sigma is simply a process for solving a problem.

Six sigma process. There are a variety of choices available and. Dari sini dapat disimpulkan bahwa Six Sigma sering digambarkan dengan simbol 6σ. An essential feature of any Lean Six Sigma project is a process map it helps explain the process at the heart of the project and directs you to unique target areas.

The end result should be the reduction of defects from a process. It consists of five phases. This saves resources time effort and most of all money.

Something that is within -6s Six Sigma from the centerline of a control chart was created by a process that is considered well controlled. This process is also known as DMAIC duh-may-ik its acronym. Process mapping provides a powerful tool for displaying the steps inputs and outputs and other related details of a process by providing an as-is and step-by-step picture of the process.

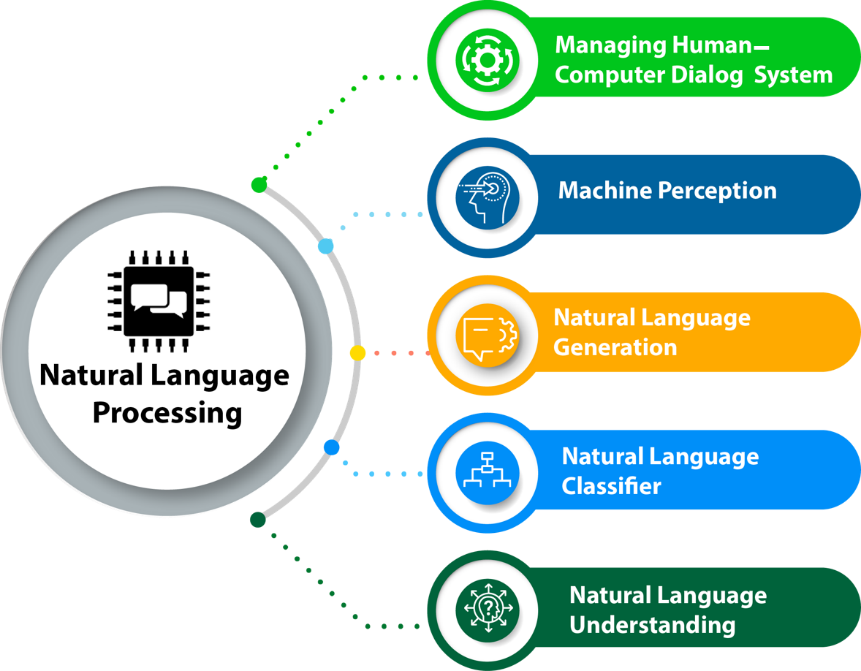

One of the core techniques behind any process improvement particularly in Six Sigma is DMAIC. SIX SIGMA berasal dari dua kata SIX yang berarti enam 6 dan SIGMA yang merupakan satuan standar deviasi yang dilambangkan dengan menggunakan simbol σ. Six Sigma DMAIC Process - Measure Phase - Measurement System The Objective of this section is to identify and understand the components of variation arising out of the measurement system and to be able to use the appropriate tool for analysis depending on the data type.

It provides methods to improve efficiencies in a business structure improve the quality of the process and increase the bottom-line profit. Semakin tinggi sigma maka akan semakin baik pula kualitasnya. The word Sigma itself means to measure how much deviation a process has been showing.

What is a Six Sigma Process Map. The concept behind this approach is to reduce the variation in processes. Six Sigma is a highly efficient method or process through which organizations can improve their products and services to the nearest perfection.

It can also be employed if a current process requires more than just incremental improvement. It is a developmental approach to delivering highly efficient and improved processes. Six Sigma uses a data-driven management process used for optimizing and improving business processes.

The Six Sigma DMADV process define measure analyze design verify is an improvement system used to develop new processes or products at Six Sigma quality levels. The Six Sigma Process of Business Transformation Although what is Six Sigma uses various methods to discover deviations and solve problems the DMAIC is the standard methodology used by Six Sigma practitioners. The Importance of People in Six Sigma.

Its a methodology which aims at improving process and increasing customer satisfaction Both internal external. The method uses a data-driven review to limit mistakes or defects in a corporate or business process. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits employee morale and quality of products or services.

Six Sigma is a method that provides organizations tools to improve the capability of their business processes. A sigma is a measure of standard deviation abbreviated as small s or the Greek letter σ. The Six Sigma school of thought is all about finding the right focus and tightening up processes around that goal.

Definisi Six Sigma. Six Sigma derives from statistical process modeling in manufacturing. Six Sigma is a measurement-based strategy for process improvement.

This handy approach pronounced duh-may-ik is the key to employing Six Sigma and beginning your journey to being a process hero. Introduction to Six Sigma Process. Define Measure Analyze Improve Control.

Were going to cover each step in the process and detail how to effectively enact every section. Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process. This reduction leads to consistent and desired outcomes from processes.

/cdn.vox-cdn.com/uploads/chorus_asset/file/19293330/Screenshot_2019_10_16_at_3.04.41_PM.png)