While Kaizen and Lean both look at resources and ways to optimize a process the core goal of Six Sigma is achieving consistent and reliable results. Salary of in house experts training process redesign.

A Comparison Between Kaizen And Six Sigma Process Exam Process Exam

A Comparison Between Kaizen And Six Sigma Process Exam Process Exam

Both philosophies aim for continual improvement of a business by creating more efficient business processes reducing waste and eliminating defects.

Kaizen vs six sigma. Similar to a comparison of Lean. Kaizen is a continuous action rather than a particular state of being you must reach. Six Sigma is more focused on quality output the final product.

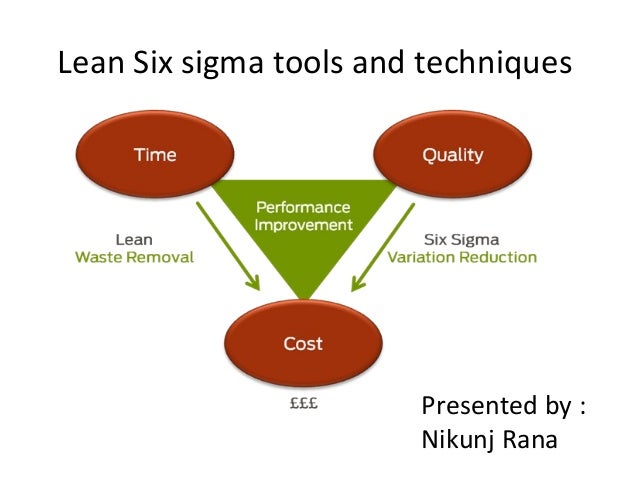

KAIZEN looks to improve all aspects of a business through standardizing processes increasing efficiency and eliminating waste by involving everyone while Six Sigma focuses more on improving the quality of the final product by finding and eliminating causes of defects whether by variances Sigma is a mathematical term that measures a process deviation from perfection in the business process or in manufacturing and Lean focus on elimination of. This way of thinking does not only makes any sense it also hides differentiation. Kaizen March 3 2017 As two management philosophies Six Sigma and Kaizen have some similarities.

In general six sigma vs kaizen is different in their approach. Profit thru quality 3. Six Sigma Vs Kaizen 1.

Six Sigma vs Kaizen. After WWII it was first used in a formal context. You start the process by finding an area of opportunity in your life.

Overall assessment of Lean vs Six Sigma vs Kaizen The overall assessment of Kaizen Six Sigma and Lean Kaizen includes innovation creativity and leadership. Kaizen works well in slow-growth economy whereas six sigma is better suited to fast-growth economy. Executives continue to send their employees off to Six Sigma Lean or Kaizen boot camps to learn the tools but they are often disappointed with the lack of results.

The word Kaizen has Japanese origins and roughly translated means constant change. The main difference between Six Sigma and Kaizen is that Six Sigma uses technical data that are oriented to solve product deviations. Lean Kaizen or Six Sigma would not be needed anymore since we now have Agile.

The process behind how it works is actually quite simple. Unlike Six Sigma which involves a project team of specialists all employees can participate in Kaizen initiatives. It encourages creativity and ingenuity to change your company culture for the better requiring like Six Sigma a team effort by which to solve problems of waste.

Kaizen is a thinking process that involves you making small physical changes in your life or at your job. Kaizen tries to improve the business as a whole by creating a standard way of working increasing efficiency and eliminating business waste. While six sigma pays attention to consistency and variation kaizen focuses on continuous improvements.

KAIZEN-The Concept Kaizenmeans improvement Ongoing improvement Involves everyone Both Managers Workers Kaizen Philosophy Our way of life need to be constantly improved Working life social life home life Kaizen embodies Productivity Improvement Total. So it is important that organizations must know whether they. The terms Kaizen originates from ancient Japanese philosophy.

6σ Kaize n Profit thru Quality 2. It is primarily focused on improving the quality of the result or outcome of the process. Executives who develop a working knowledge of Six Sigma Lean and Kaizen are much better prepared to build the right infrastructure and lead their organizations to both financial and human success.

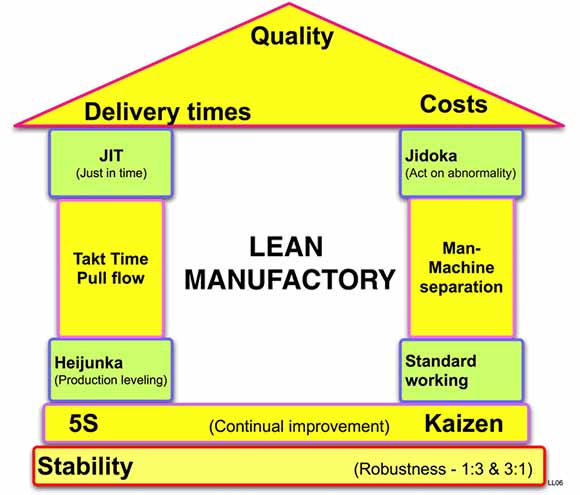

Finally the influence of the Kaizen approach extends to many other major frameworks in use today including Kaizens direct successor Lean Manufacturing an alternate framework known as Six Sigma and the combination of both of these models known as Lean Six Sigma all of which incorporate the Kaizen approach as a foundational principle in their models. When the team of leadership understands Lean Kaizen and Six Sigma system they can always improve themselves have clearer and better focus on what can be done in order to boost and improve competitiveness and profitability. There is a significant contrast between the Kaizen principle and the Six Sigma.

Six Sigma Results Six Sigma Savings as of revenue vary from 12 to 45 For 30 millionyr sales Savings potential 360000 to 135 million. Six sigma makes use of statistical analysis while kaizen does not. However six sigma vs kaizen helps businesses to reduce costs improve productivity and boost profitability.

In contrast Kaizen focuses on making work environments better which has a positive impact on overall performance. In this video I have explained differences in all these 3 important industrial practices in several categories in HindiTo explore our Online courses on KAIZ. In order to do so the company must ensure that it trains its employees about.

When it was first invented the concept was to strive relentlessly for success in all aspects of an individuals life.

.jpg)